Disrupting the Carbon Black Industry with Biobased Alternatives

Including innovative biobased options from Origin Materials and Nature Coatings. Plus: Mycelium in Fashion, Flax Composites for Automobiles, and Industry News

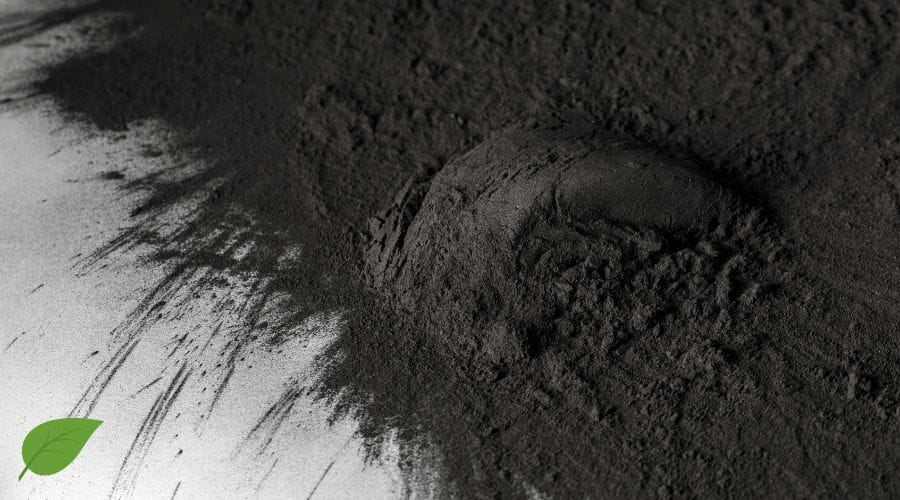

Biobased Alternatives to Carbon Black

Carbon black is produced from incomplete combustion or thermal decomposition of hydrocarbons. Approximately 90% of carbon black produced is used in rubber applications (i.e. tires), with the remaining used as a pigment for inks, coatings and a myriad of other applications.

With approximately 14 million tons of carbon black produced every year, it’s one of the top 50 globally produced industrial chemicals. And, due to its fossil origins, which generate polycyclic aromatic hydrocarbons (PAHs) and emissions of 35-40 million tons of CO2 per year, the carbon black industry seems to be a good candidate for disruption with more sustainable alternatives.

Which leads us to innovative companies such as Origin Materials and Nature Coatings.

Origin Materials offers a groundbreaking replacement for petroleum-derived carbon black, produced from wood residue instead of oil. This 100% bio-content product is cost-competitive and boasts customizable properties. Notably, it lacks the carcinogenic compounds often found in conventional carbon black, ensuring both safety and stable pricing.

BioMade, in collaboration with Origin Materials and the University of California-Davis, is working on decarbonizing military fleets using bio-based carbon black from agricultural waste.

Nature Coatings introduces BioBlack TX, a carbon-negative water-based dispersion derived from FSC-certified wood waste. It exhibits exceptional lightfastness, surpasses industry standards for safety with no detectable PAHs and minimal VOCs, and is sourced from sustainably managed and certified sources.

BioBlack TX serves as a direct replacement for petroleum-derived carbon black, making it a sustainable and renewable option across various applications, from printing to coatings.

Mycelium in Fashion Applications: Sustainable Threads

Mycelium is the vegetative part of a fungus, consisting of a network of thread-like structures called hyphae. It serves as the root system of fungi and plays a crucial role in decomposing organic matter, nutrient absorption, and forming symbiotic relationships with plants. And, thanks to its remarkable performance properties, mycelium has become one of the most exciting building blocks for sustainable product development.

Many of us are already aware of mycelium’s place as a sustainable binder and moldable material for replacement of EPS foam in packaging applications. Perhaps less known, however, is mycelium’s potential as a groundbreaking material in fashion and apparel applications.

One example of mycelium in fashion applications is Fine Mycelium™, a groundbreaking technology developed by MycoWorks. One of the standout products derived from Fine Mycelium™ is Reishi™, a premium material that mimics the strength and feel of animal leathers while minimizing the environmental impact.

Also, Forager hides, grown using Ecovative's Air Mycelium™ technology, provide a synthetic-free, vegan leather alternative. These hides exhibit impressive characteristics such as high tensile strength and tear resistance, comparable to traditional leathers.

And SQIM, the company behind Mogu, recently introduced EPHEA™️, a novel class of flexible mycelium materials designed for fashion and beyond. While not a leather replacement, EPHEA™️ sets a new standard in the industry, offering unique values, functionalities, and opportunities through mycelium-based biofabrication.

Your Next Car Might be Made with Flax

In the automotive industry's pursuit of sustainability and innovation, flax composites have emerged as a game-changing material. These composites, produced using flax fibers, offer comparable strength and stiffness to traditional materials like glass and carbon fiber-reinforced plastics but come with a significantly smaller carbon footprint.

One standout advantage of flax fiber-reinforced composites is their exceptional vibration-damping properties, effectively reducing noise, vibration, and harshness (NVH). Also, flax composites do not succumb to brittle fracture and splintering upon impact, enhancing safety for trim and exterior parts in the event of a collision. Flax's low density also proves to be a critical benefit, particularly for electric vehicle manufacturers grappling with substantial battery pack weights.

If you're looking for examples of how flax is being integrated into automobile design, look no further than high-end car brands including Volvo, BMW, Porsche, and the French sports car company, Alpine. And what most of these brands have in common is that they're using Bcomp's amplitex.

Bcomp, the Swiss-based composites company that manufacturers amplitex, is known for producing sustainably engineered flax fabrics that excel in vibration damping, surpassing glass and carbon fibers, resulting in smoother rides and reduced fatigue.

Other car companies, including Hyundai, are also using flax-based materials for natural veneers in automotive interior applications, including instrument panels, door spears, and seat backs. In this case, Hyundai worked with Lingrove, the company that devevelops the lightweight and sustinable brand Ekoa®.

We Shared . . .

News and Links from the Bioeconomy

+Genera Expands Biomanufacturing Capacity

Genera, a biomaterials company, is expanding its Sustainable Biomaterials Campus in Tennessee with a $350 million investment to increase manufacturing and production of sustainable packaging solutions.

+A Roadmap for Sustainable Chemistry

In the assessing the NSTCs Sustainable Chemistry Report, these authors advocate for a more comprehensive and highly coordinated approach to sustainable chemistry that addresses environmental challenges, promotes innovation, and creates economic opportunities.

+How AI Could Benefit Biomanufacturing

Introducing AI-based protein design capabilities could enable the generation of new-to-nature enzymes fine-tuned for specific manufacturing tasks. This could potentially unlock unit economics that could rival those of traditional manufacturing practices.